Ford Focus ST

This car is very well known in the Ford car scene. The owner of this particular Focus ST had seen the vast improvement in the Frozen White Focus RS that we coated in Feynlab Heal Lite and wanted his own car to look the same.

I arrived and set about thoroughly washing the vehicle and removing any tar and iron deposits from the paintwork and finishing off the decontamination process by using a clay sponge and spray detailer. A noticeable difference is how much easier the paint is to work on on this model Focus St against how grabby the paint was on the Focus RS.

We were very busy and the owner has trained with us on using a da polisher and wanted to do as much of the polishing as he could himself. He spent two days on it to remove as much as he could and we removed a number of deeper scratches from the paintwork and refined it to ensure it was ready for one of Feynlab’s flagship coatings! We also deep cleaned the wheels by removing any tar and iron in preparation for the wheel coating.

We then performed a deep clean on the interior with all of the interior carpeting and removable mats getting an intensive wet extraction to remove any embedded dirt. We then full dried the interior and applied Feynlab Textile to the fabric of the seats, carpeting and removable mats making the maintenance far easier in the future.

The rear seats and front seats are leather and were deep cleaned using KKD Lush Leather gel kit and we coated the leather using Feynlab Leather coating.

While the Textile and Leather coating were curing we moved onto the exterior and applied Feynlab Wheel and Caliper to the wheel faces and allowed it to cure and removed the excess with a high quality GSM microfibre.

The pre coating stages are essential to how well the coating will bond and perform when installed and Feynlab has that area covered as well ! Feynlab Wash flushes out any oils or airborne contaminants that may have become embedded in the paintwork when polishing. We then follow that process up with Feynlab Prime which fills in any microscopic indentations that the polishing process could not remove and leaves down an excellent “key” for the coating to adhere to.

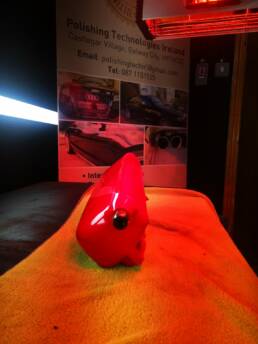

The exterior was then wiped down with Feynlab Panel Wipe to ensure a crisp clinically smooth surface Ceramic Lite was applied to the windows and Plastic was applied to the window rubbers, windscreen cowling, front headlight and rear tail lights to protect it from the high solid content that the Heal Lite coating has.

Feynlab’s 5 year Heal Lite 60% self healing coating was applied one panel at a time allowed to dwell and I removed any high spots to leave the paintwork gleaming. We then after the required time set out by Feynlab applied Top Coat which adds a hydrophobic boost to the coating leaving it silky smooth to the touch.

Following on from this coating taking place we then coated a new aftermarket set of alloy wheels, wishbones, big brake conversion and intake plenum in Wheel and Caliper, ensuring every section of metal available has been coated in the relevant coating from the Feynlab range.